FR-4 PCBs

FR-4 PCBs

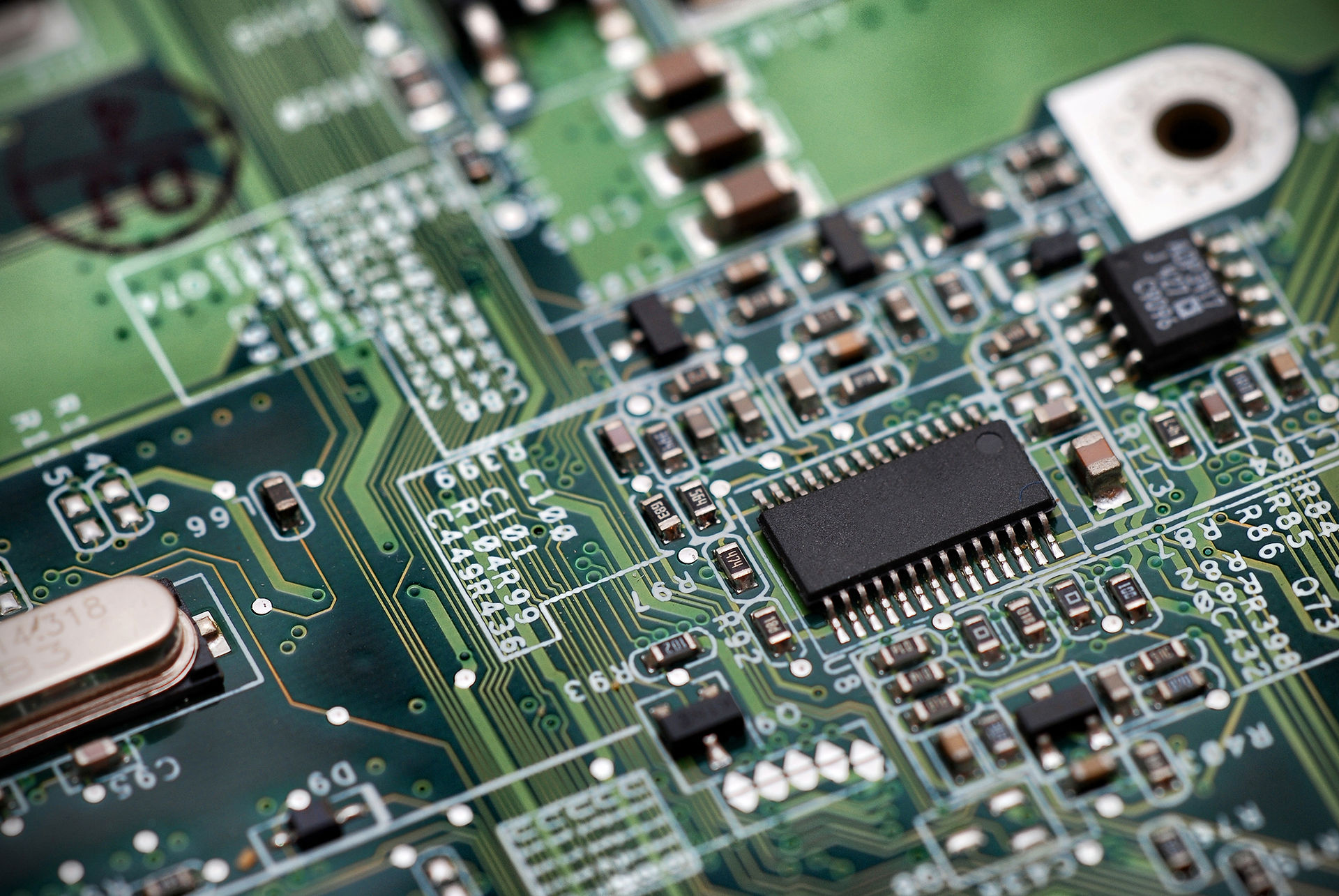

Most people don't realize that everything is controlled with a PCB. Whether it's your mouse, your keyboard, your phone, your TV, or your router, electronics are dependent on PCBs.

FR-4 is the material upon which the vast majority of PCBs are made. FR-4 PCBs are seen as the standard PCB because of its cost-effectiveness. For applications that don’t produce extreme heat, FR-4 PCBs are your tried-and-true solution.

FR-4 copper-clad sheets are fabricated with circuitry etched into copper layers and become more complex as more layers are added. A thin layer of copper foil is laminated to one or both sides of an FR-4 glass epoxy panel, commonly referred to as “copper clad laminates.”

For more information on FR-4 PCB capabilities and how we can customize these boards for you, please see PCB Capabilities.

Process

Item

Normal SPEC

Special SPEC

01/

Material

150℃ to 180℃

Layer count

16L

20L

02/

Mask

Color

Green / blue / Red / Black / White / Golden / Clear

03/

Silkscreen

Color

White / Black / Red / Yellow

04/

Testing

1. Open / Short Testing Spacing

2. Open / Short Board Size

3. Open / Short Testing Condition

4. Netlist Test

Dedicate: 6ml

Fly probe Spacing: 4mil (Smd Pitch: 10 mil)

Dedicate: 600x400mm(max)

Fly probe: 640x450mm(max)

Dedicate: 250V / 50Ω / 2MΩ

Fly probe: 250V / 50Ω / 10MΩ

min / max: 1MΩ ~ 20MΩ

1). Measure Machine: POLAR

2). Tolerance: ±10%

3). design: Single End / Differential ±10%

4). Testing Pitch: 0.254mm

Tolerance 5%

05/

Finish Type

HASL

Carbon Ink

Imm gold

Hard gold

Imm Tin

Leadfree HAL

Imm Silver

Imm Gold+HASL

Imm Gold+ENTEK. Carbon+ENTEK

Imm gold+G / F(3~30μ)

Partial Hard Gold

Partial Imm Gold

Imm Gold + SMOBC

Density

Thickness Tolerance

Thickness (Minimum / Maximum)

QFP

Minimum Solder mask Web

Minimum Prepreg Fill

Minimum Line/Spacing - Internal 1/2 oz

Minimum Line/Spacing - External 1/2 oz

Minimum Drilled Hole Size

Minimum Core Thickness

Layer to Layer Registration

Land Size (Diameter over Drill)

BGA

Aspect Ratio - Line Card

+/- 8

7 / 300

0.5 mm

0.005

.0025

.004

.004

.008

.004

+/- .005

.010

.5 mm

12:01

+/- 6

5 / 440

.4mm

.004

.002

.003 1/3 oz

.003 1/3 oz

.006

.003

+/- .003

.008

.4mm

14:01

Title

Standard

Advanced & Development

HDI VIAS

Microvia Aspect Ratio

Variable Depth Laser Via (Depth / Diameter)

Minimum Laser Via (Drill / Capture Pad)

BBV Mechanical Drill

.5:1

.004/.006

.006/.016

.010

.004/.005

.005/.014

.008

Title

Standard

Advanced & Development

Impedance Control

28 - 260Ohms

50 - 150 Ohms

+/-10%

+/-10%

+/-7%

+/-7%

Title

Standard

Advanced & Development

Copper Weights

Min Outer Base Copper - plated layers

Max Outer Base Copper - plated layers

Max Inner Copper Foil - non plated layers

Min Inner Copper Foil - non plated layers

1/2 oz

5 oz

4 oz

1/4 oz

1/4 oz

5 oz

5 oz

1/4 oz

Title

Standard

Advanced & Development